From sealing envelopes to holding spacecraft together, adhesive tape is one of the most ubiquitous yet overlooked items in our daily lives. We peel, stick, and tear without a second thought about the incredible science and engineering packed into that thin strip. It seems simple, but the humble roll of tape is far more complex than it appears, involving intricate chemistry, physics, and a fascinating history. Let’s explore the hidden world of adhesive tape – its origins, how it works, what it’s made of, modern innovations, and how to pick the right one for the job. For a general overview of what adhesive tape is, you can start with its definition on Wikipedia.

More Than Just Sticky: What is Adhesive Tape?

At its core, adhesive tape is defined as a material backing coated with an adhesive. This simple structure typically involves a backing material (like plastic film, paper, or cloth) that provides strength and structure, and an adhesive layer applied to one or both sides. Some tapes also include a release liner to protect the adhesive until use, particularly with double-sided or specialty tapes.

The world of adhesive tape is astonishingly diverse. Tapes are engineered for specific tasks across virtually every industry: securely closing packaging, binding cables in electronics, sealing joints in construction, holding bandages on skin in medicine, enabling precise two-tone painting in automotive, and even providing structural bonds strong enough to replace rivets in aerospace. It’s not just a single product; ‘tape’ is a category encompassing thousands of highly specialized and engineered solutions.

A Sticky History: From Ancient Glues to Modern Miracle

The concept of sticking things together is ancient, predating recorded history.

Early Adhesives: Nature’s Stickiness

For millennia, humans relied on natural substances for adhesion. Ancient civilizations used glues derived from tree resins, animal products like collagen from hides and bones, beeswax, and natural rubber latex. These early adhesives were vital for crafting tools, repairing pottery, building structures, and even in practices like mummification, showcasing humanity’s early understanding of how to harness nature’s sticky secrets.

The Birth of Modern Pressure-Sensitive Tape

The invention of modern adhesive tape as we know it began in the 20th century. In the 1920s, Richard Drew at the 3M Company invented masking tape. Painters needed a way to create clean lines when applying two-tone paint to cars without damaging the first layer. Drew’s solution was a crepe paper-backed tape with a weaker adhesive that could be easily removed, solving a persistent problem in manufacturing. Later, 3M developed cellophane tape, famously known as Scotch Tape, which became a household staple, especially during the Great Depression, offering a quick fix for countless minor repairs. During World War II, a strong, waterproof cloth tape (now known as duct tape) was created for the military to seal ammunition boxes and repair equipment in the field. Its original color was green. Post-war, it transitioned to its familiar silver-gray color and found millions of uses in civilian life. The mid-20th century saw a boom in specialized tapes like electrical tape, packing tape, and medical tapes, driven by new materials and evolving needs.

The Deep Science of Stick: How Adhesion Really Works

Tape’s ability to stick is a fascinating interplay of physics and chemistry, far more complex than simply being ‘sticky’.

The Physics and Chemistry of Adhesion Explained

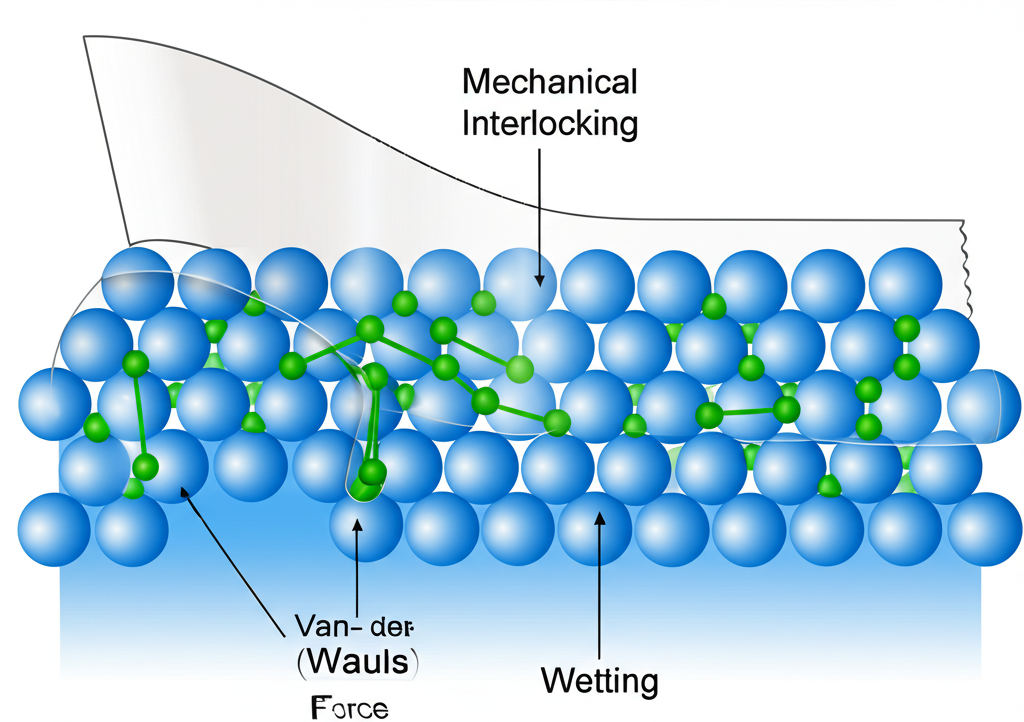

Adhesion, the force that makes tape stick to a surface, is distinct from cohesion, the internal strength holding the adhesive mass together. Multiple mechanisms contribute to tape adhesion:

- Mechanical Interlocking: The adhesive flows into tiny pores and irregularities on a surface, hardening slightly to create a physical anchor, much like a key fitting into a lock.

- Electrostatic Attraction: While less significant for common tapes, static electricity can play a minor role, similar to how a balloon sticks to a wall.

- Diffusion Bonding: This involves molecules of the adhesive and the surface mixing. It’s more relevant in bonding similar materials under heat/pressure, less so for everyday tapes.

- Chemical Bonding: The formation of strong primary chemical bonds (covalent, ionic) between the adhesive and the surface. This creates very strong, often permanent bonds, found in structural adhesives but usually not in tapes designed for easy removal.

- Adsorption and Surface Energy (Wetting): The adhesive must spread out or ‘wet’ the surface effectively to maximize contact. This depends heavily on the surface energy of the material being taped. High surface energy surfaces (like metal or glass) are easier for most adhesives to wet than low surface energy surfaces (like many plastics), where the adhesive tends to bead up.

- Van der Waals Forces: These are weak, short-range intermolecular forces present between all molecules. They are individually weak, but when a large area of adhesive comes into very close contact with a surface (like with tape), the cumulative effect of billions of these forces becomes substantial, providing significant adhesion. This is a key mechanism for Pressure-Sensitive Adhesives.

Pressure-Sensitive Adhesives (PSAs): The Everyday Magic

Pressure-Sensitive Adhesives (PSAs) are the most common type used in tapes. They form a strong bond simply by applying light pressure, requiring no water, solvent, or heat activation. PSAs work by achieving a delicate balance of properties:

- Tack: The initial ability to stick immediately upon brief contact.

- Adhesion: The strength of the bond that develops over time after initial contact and pressure.

- Cohesion: The internal strength of the adhesive itself, which prevents it from splitting apart or leaving residue when the tape is removed.

PSAs are typically made from polymers like acrylics or rubber-based compounds. Scientists precisely tune the polymer composition, adding tackifiers and plasticizers, to achieve the specific balance of tack, adhesion, and cohesion needed for a tape’s intended use, from easily removable masking tape to aggressively sticky packing tape.

The Backing Story: Materials Matter

While the adhesive does the sticking, the backing material plays a critical role in the tape’s performance and characteristics. It’s the backbone that holds the adhesive, provides strength, and dictates how the tape handles and performs under different conditions.

The backing can provide essential properties such as:

- Strength and Tear Resistance: How much force the tape can withstand before breaking.

- Flexibility and Conformability: How well the tape can bend and conform to irregular surfaces.

- Temperature Resistance: The range of temperatures the tape can function in.

- UV Resistance: Protection against degradation from sunlight.

- Ease of Tearing: Whether the tape can be torn by hand or requires a dispenser.

Here’s a look at common backing materials:

| Backing Material | Common Tape Types | Key Properties |

|---|---|---|

| Plastic Films | Packaging (OPP), Electrical (PVC), Specialty (PET) | Transparent/Opaque, Strong, Moisture Resistant, Electrical Insulation (PVC) |

| Paper (Creped) | Masking Tape | Conformable, Easy Tear, Paint Bleed Resistance |

| Paper (Flatback) | Some Packaging, Strapping | High Strength, Less Stretchable than Creped Paper |

| Cloth/Fabric | Duct Tape, Gaffers Tape | High Strength, Flexible, Hand Tearable, Conformable |

| Foam | Mounting Tape (e.g., some VHB) | Gap Filling, Vibration Damping, Conformable, Seals |

| Metal Foils | HVAC, Shielding, Reflective | Temperature Resistance, Conductivity, Barrier Properties |

The choice of backing is crucial; a flexible PVC is perfect for electrical insulation, while a strong, non-stretch OPP is ideal for sealing heavy boxes.

Modern Innovations and Specialty Tapes

Adhesive tape technology continues to evolve, pushing the boundaries of what these materials can do. Modern innovations have led to highly specialized tapes designed for demanding applications.

- Extreme Performance Tapes: Engineered to withstand extreme temperatures (both high and low), exposure to harsh chemicals, solvents, or prolonged UV radiation without losing adhesion or degrading.

- Medical Tapes: Developed to be gentle and breathable on skin while providing secure adhesion for bandages, surgical drapes, device fixation, and wearable sensors. Adhesion levels are carefully calibrated for easy, non-damaging removal.

- Electronic Tapes: Used for insulation, conductivity, shielding electromagnetic interference (EMI), and thermal management within sensitive electronic devices.

- Structural Bonding Tapes: Products like 3M’s VHB™ (Very High Bond) tapes are strong enough to replace mechanical fasteners like rivets, screws, and welds in industries from automotive and construction to electronics assembly, offering cleaner lines and faster assembly processes.

- Functional Tapes: Tapes with integrated features, such as indicator tapes that change color based on temperature or humidity, tamper-evident security tapes, or even tapes with embedded sensors.

- Sustainability: Growing focus on using recycled content in backings, developing solvent-free adhesive manufacturing processes, and creating tapes with biodegradable components.

These innovations demonstrate that adhesive tape is far from a static technology; it’s a dynamic field of material science and engineering.

Choosing the Right Tape: It’s Not One-Size-Fits-All

</br/>

Given the vast array of tapes available, selecting the correct one for a specific task is key to success and preventing frustration. Using the wrong tape is a common reason for failure.

Here are the crucial factors to consider:

- Surface Type: Is the surface smooth, rough, porous, painted, or textured? What is its surface energy (e.g., easy-to-stick metal/glass vs. harder-to-stick plastics)? This impacts how well the adhesive can wet and bond.

- Environmental Conditions: What temperature range will the tape be exposed to? Will it encounter humidity, water, sunlight (UV), or chemicals? These factors can significantly affect adhesive performance and backing integrity.

- Duration of Bond: Do you need a temporary hold (like masking tape for painting) or a permanent, long-term bond?

- Stress/Load: How much weight or force will the tape need to bear? This determines the required adhesion strength and backing durability.

- Removal Requirements: Do you need the tape to remove cleanly without leaving residue or damaging the surface, or is permanent application acceptable?

Tape failure can occur in several ways: adhesive failure (tape lifts cleanly from the surface), cohesive failure (adhesive splits internally, leaving residue on both surfaces), or delamination (backing separates from the adhesive). Understanding the application and choosing a tape engineered for those specific conditions is the best way to ensure a successful bond.

Conclusion

What seems like a simple household item – a roll of tape – is in fact a sophisticated product born from centuries of ingenuity. From ancient humans using natural glues to modern engineers developing high-strength structural adhesives and smart tapes, the journey of adhesion technology is remarkable.

Adhesive tape stands as a testament to how history, complex science, and advanced engineering can converge in an everyday object. Next time you reach for a roll, take a moment to appreciate the unseen complexity and the vital role this sticky technology plays in holding our modern world together.

FAQ

Q: What is the difference between adhesion and cohesion?

A: Adhesion is the strength of the bond between the tape’s adhesive and the surface it’s applied to. Cohesion is the internal strength of the adhesive itself – how well the adhesive molecules stick to each other. Both are important for tape performance.

Q: Why do some tapes leave sticky residue?

A: Leaving residue is often a sign of cohesive failure in the adhesive or using a tape not designed for clean removal or prolonged application. The adhesive’s internal strength (cohesion) isn’t sufficient to peel away cleanly, or it degrades over time.

Q: Can tape stick to wet surfaces?

A: Most standard tapes do not stick well to wet surfaces because water prevents the adhesive from properly wetting and making close contact with the surface. Some specialized tapes are designed with water-resistant adhesives for damp environments, but dry surfaces are usually best.

Q: What makes duct tape so strong and versatile?

A: Duct tape’s strength comes primarily from its cloth or fabric mesh backing, which provides high tensile strength. Its thick, aggressive rubber-based adhesive contributes to its strong grip on many different surfaces, making it versatile, though not always ideal for clean removal.