Introduction

Step back in time and consider the impossible. Imagine civilizations, thousands of years ago, lifting colossal stones, precisely shaping mountains, and transporting water over vast distances – all without the aid of steel cranes, combustion engines, or complex computer modeling. Structures like the Egyptian pyramids, the intricate stonework of Machu Picchu, and the sprawling Roman aqueducts continue to stand as silent testaments to an almost unbelievable level of ancient ingenuity. If you’re interested in learning more about these historical periods, a wealth of resources can be found at the History Channel.

How exactly did they achieve these feats? Without modern tools, advanced machines, or the theoretical physics we rely on today, how did ancient engineers conquer challenges that would daunt even us? The methods remain a subject of intense study and fascinating debate among historians and engineers alike.

This post will delve into some of the most astonishing examples of ancient engineering marvels. We will explore the specific obstacles faced by these early builders and examine the clever, practical, and often deceptively simple techniques they likely employed to overcome them.

We will journey from the sands of Egypt to the heights of the Andes, across the Roman Empire, and into the heart of ancient Mesoamerica. Along the way, we’ll marvel at massive stone structures, sophisticated water systems, incredibly precise alignments, and the sheer willpower that brought these wonders to life.

Why Ancient Engineering Is So Mind-Boggling

The Technology Gap

The difference between ancient tools and modern construction technology is staggering. Ancient builders relied on simple levers, ropes made from natural fibers, rollers, and basic hand tools crafted from stone, bronze, or iron. Compare this to today’s cranes that lift tons effortlessly, bulldozers that move mountains of earth, and laser levels providing pinpoint accuracy. The lack of advanced metallurgy and power sources meant every task, from quarrying to lifting, required immense physical effort and clever mechanical advantage derived from basic principles.

Furthermore, these civilizations did not possess the formal understanding of physics, structural mechanics, or complex mathematics that forms the basis of modern engineering education. Their knowledge was empirical, built upon generations of practical experience, trial and error, and inherited wisdom. It was a deep, intuitive understanding of materials and forces, honed by doing rather than theoretical calculation.

Scale and Precision

The sheer scale of some ancient projects defies easy explanation. Imagine moving and lifting stones weighing dozens or even hundreds of tons, sometimes over significant distances. Consider constructing buildings hundreds of feet high, like the Great Pyramid, or creating vast urban centers laid out with remarkable precision. These were not small endeavors.

Equally astonishing is the precision achieved. Stone blocks in some structures, like Inca walls or Egyptian temples, fit together so tightly that a knife blade cannot be inserted between them. Astronomical alignments in pyramids, temples, and city plans are accurate to degrees or even fractions of a degree. Modern engineers often find themselves attempting to “reverse engineer” these structures, analyzing tool marks and construction methods to deduce the lost techniques of these ancient masters.

Case Study 1: The Pyramids of Egypt

Building on an Impossible Scale

The pyramids of Egypt, particularly those at Giza, represent construction on an unprecedented scale. The Great Pyramid alone is composed of approximately 2.3 million stone blocks. While the average weight is around 2.5 tons, some stones, like those used for the King’s Chamber roof, weigh between 50 and 80 tons. Sourcing these stones involved quarrying limestone locally for the bulk and granite from as far away as Aswan, over 500 miles south.

Transporting these massive blocks likely involved boats on the Nile River during the annual flood, bringing stones close to the Giza plateau. Moving them over land is theorized to have used sledges pulled over sand lubricated with water, or perhaps rolling mechanisms. The most widely accepted theories for lifting involve ramps built around or within the pyramid structure – debate continues whether these were straight, spiral, or a combination. Simple levers were also likely crucial for fine positioning.

The construction demanded an immense workforce, estimated to be in the tens of thousands. Evidence suggests these were skilled laborers, well-fed and housed in temporary cities built near the construction site, rather than being exclusively slave labor as sometimes depicted. Organizing, feeding, and managing such a large crew was an engineering and logistical feat in itself.

Precision and Alignment Secrets

The accuracy of the Great Pyramid is astounding. Its base is square to within a few inches, and its sides are aligned almost perfectly with the four cardinal directions, oriented within 1/15th of a degree of true north. This alignment was likely achieved using astronomical observations, possibly tracking the movement of circumpolar stars that seemed to revolve around true north, or by observing the sun’s path.

The angles of the pyramid’s sides are incredibly consistent. Inside, the King’s Chamber, built with heavy granite, shows remarkable precision in its construction and the fitting of its large stones. The complex network of internal passages, shafts, and chambers, all built within this vast stone mountain, required sophisticated planning and execution.

- Key Statistics:

Blocks in Great Pyramid: ~2.3 million

Average block weight: ~2.5 tons

Heaviest blocks: 50-80 tons

Alignment to True North: within 0.06 degrees

Case Study 2: Machu Picchu and Inca Stonework

Building in a Challenging Environment

Machu Picchu, perched high in the Andes mountains, presents a unique set of engineering challenges. Located on a narrow ridge between two peaks, it is both remote and sits in a seismically active zone prone to landslides and heavy rainfall. The Inca builders had to integrate their city seamlessly into this dramatic and precarious landscape.

They masterfully engineered the site by carving extensive terraces into the steep slopes. These terraces were not just for agriculture; their complex layered construction with gravel and soil acted as a natural drainage system. This system was vital for channeling rainwater away from the buildings and slopes, preventing erosion and landslides and providing structural stability to the entire site.

The Art of Ashlar Masonry (No Mortar!)

The defining characteristic of Inca construction at Machu Picchu and other sites like Sacsayhuaman is their extraordinary dry-stone masonry, known as ashlar. Massive stones, often multi-sided and irregularly shaped, are cut and fitted together with such precision that no mortar was needed to hold them in place. The joints are so tight it’s often said you cannot fit a knife blade between them.

The methods used to shape and fit these stones remain somewhat debated. Theories suggest repeated hammering with harder stones (like hematite), abrasion using sand and water, and perhaps intricate templating and trial-and-error processes. The result is a flexible yet incredibly strong wall. This interlocking, mortarless construction proved highly resistant to the frequent earthquakes in the region. When tremors occur, the stones can shift slightly, then settle back into place, unlike rigid mortared walls which tend to crack and collapse.

- Inca Stonework Techniques:

Dry-stone masonry (no mortar)

Precisely cut, often multi-sided blocks

Interlocking construction for stability

Potential use of hammering and abrasion for shaping

Earthquake-resistant design

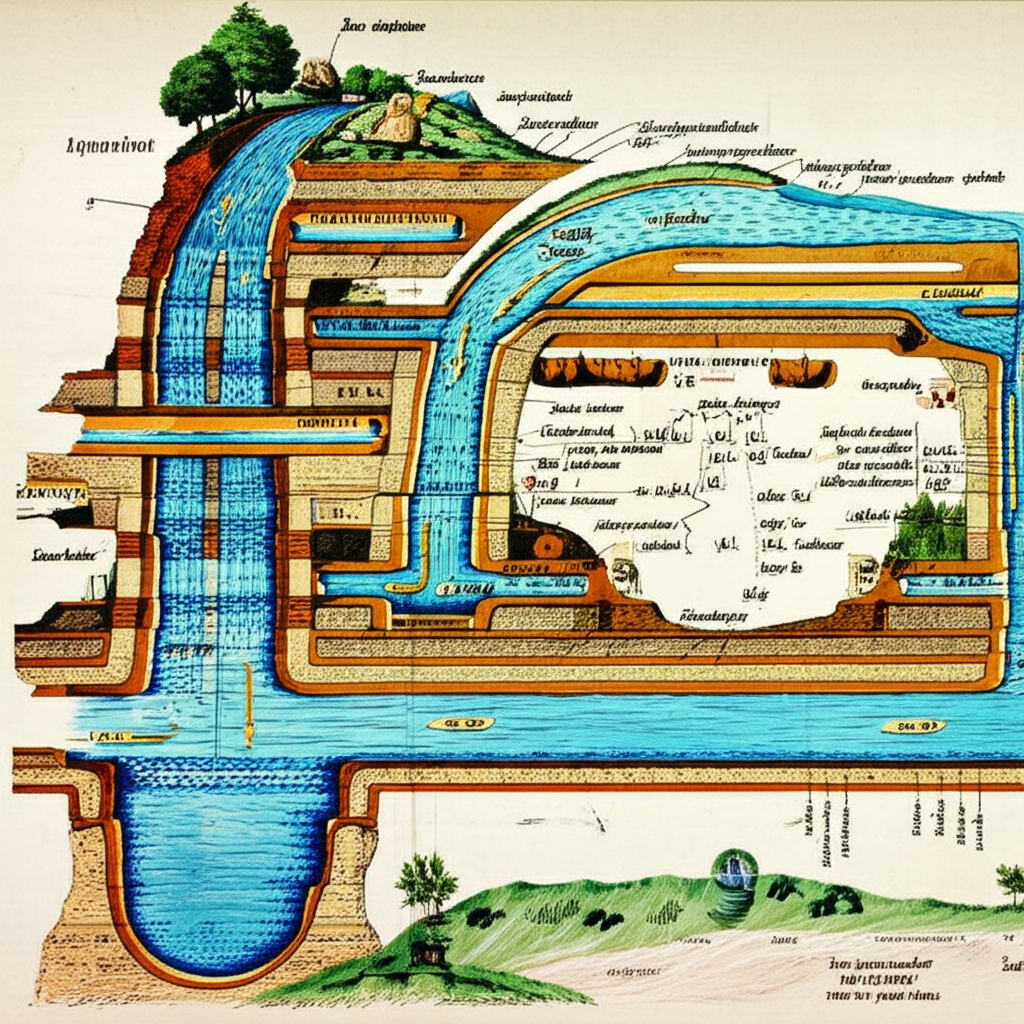

Case Study 3: Roman Aqueducts

Mastering Water Transport Over Distance

The Roman aqueducts were vital infrastructure that supplied fresh water to cities, baths, and fountains across the vast Roman Empire. Building them required overcoming significant geographical obstacles to transport water from distant sources, often miles away, down into urban centers. The core challenge was maintaining a consistent, gentle downward slope over the entire length of the aqueduct.

This required incredibly precise surveying. Roman engineers had to carefully map the terrain, identify the highest viable water source, and plan a route that ensured a continuous, slight gradient – sometimes as little as a few inches per mile (e.g., the Pont du Gard aqueduct has a gradient of about 10 inches per mile over 31 miles). They used simple tools like the chorobates (a leveling tool) and the dioptra (a surveying instrument) to achieve this remarkable accuracy across varied landscapes of hills, valleys, and plains.

Materials, Arches, and Innovation

Roman engineering was greatly advanced by their mastery of concrete, a material far superior to anything used by previous civilizations. Roman concrete was durable and could be molded, allowing for complex shapes like arches and vaults. This was often faced with stone or brick for protection and aesthetics.

The arch was a fundamental element in aqueduct construction. Its structural efficiency allowed the Romans to span valleys and ravines using less material than solid walls or ramps, creating the iconic multi-tiered structures we see today, like the Pont du Gard in France or the Aqueduct of Segovia in Spain. Beyond the visible arches, the system included covered channels, reservoirs for storage, sedimentation tanks for filtering water, and even inverted siphons using lead pipes to cross dips in the terrain where arches were impractical. Within cities, complex distribution networks of pipes and tanks ensured water reached various public and private uses.

| Structure | Location | Estimated Length (Miles) | Max Height (Feet) | Key Feature |

|---|---|---|---|---|

| Pont du Gard | France | ~31 | ~160 | Multi-tiered arches |

| Aqueduct of Segovia | Spain | ~10 | ~90 | Granite, mortarless |

| Aqua Claudia | Rome, Italy | ~43 | ~100 | Extensive use of arches |

Case Study 4: Teotihuacan, Mexico

Grand Urban Planning in Ancient Mesoamerica

Teotihuacan, flourishing centuries before the Aztecs, was not just a collection of monumental structures but a vast, planned city. At its peak, it was one of the largest cities in the world, covering over eight square miles and housing potentially over 100,000 people. The city plan itself is a marvel of engineering and organization.

It was laid out on a precise grid system, dominated by the “Avenue of the Dead,” a central axis running north-south. Major pyramids, including the enormous Pyramid of the Sun and the Pyramid of the Moon, were strategically placed along this avenue, often with astronomical alignments incorporated into their design and placement relative to surrounding mountains. This level of city planning on such a scale was unprecedented in Mesoamerica.

Construction Techniques and Materials

The builders of Teotihuacan primarily used local volcanic stone, such as tezontle, a lightweight, porous red rock, along with large quantities of lime plaster to finish surfaces. The massive pyramids were not solid stone but were constructed by creating a framework or stepped structure and then filling it with rubble, earth, and smaller stones, finally facing the exterior with dressed stone and plaster.

Beyond the pyramids and main avenues, the city featured extensive residential compounds housing multiple families, often built with internal courtyards and drainage systems. Archaeological evidence suggests a sophisticated urban infrastructure, including systems for managing water and waste, essential for supporting such a large population. The scale of construction indicates a well-organized society capable of mobilizing vast amounts of labor and resources.

Other Incredible Examples (Brief Mentions)

A Global Tapestry of Ingenuity

Ancient engineering prowess was a global phenomenon, not limited to a few famous sites. Stonehenge in England, with its massive sarsen stones (up to 30 tons) and smaller bluestones (transported potentially hundreds of miles), shows remarkable effort in moving and precisely positioning stones for astronomical alignment.

The Great Wall of China, while built over centuries by various dynasties, represents an astonishing feat of continuous construction across incredibly diverse and challenging terrain – mountains, deserts, and plains. It required adapting building materials and techniques to each specific environment over thousands of miles.

The Moai statues of Easter Island are another puzzle. These enormous stone figures were carved from volcanic rock, moved across the island, and erected upright. Theories involving ropes, levers, and specialized wooden sleds or rolling frames attempt to explain how these multi-ton monoliths were transported and raised.

In North America, the Mesa Verde cliff dwellings showcase ingenuity in adapting architecture to the environment. Ancestral Puebloans built complex, multi-story villages directly into shallow caves and under rock overhangs, utilizing the natural protection and thermal regulation of the cliffs while creating intricate living spaces. Sacsayhuaman, near Cusco in Peru, is another stunning example of megalithic Inca stonework, featuring walls of enormous, perfectly fitted stones that served as a fortress or ceremonial site, mirroring the techniques seen at Machu Picchu but on an even grander scale of individual stone size.

Unanswered Questions and Ongoing Research

Despite centuries of study, many aspects of how these ancient wonders were built remain open questions. While archaeologists and engineers have proposed plausible theories for lifting stones, achieving precision, and planning vast projects, definitive proof of every step is often elusive. Ancient records are scarce, incomplete, or non-existent regarding the practical ‘how-to’ details of construction.

Reconstructing ancient building processes is challenging. It involves interpreting tool marks, studying construction sequence evidence, and conducting experimental archaeology (like attempting to move or lift heavy stones using only ancient methods). There are inherent limitations to what archaeology can reveal about dynamic processes like construction.

Are there still mysteries about how these structures were built? While plausible theories exist for many aspects, the exact step-by-step processes, specific tools used for intricate cuts, and the precise methods of organizing and motivating vast workforces are still subjects of ongoing research and debate among experts.

Fortunately, ongoing research is leveraging modern technology. Techniques like 3D scanning create detailed digital models for structural analysis. Geophysics helps identify buried features. Material analysis provides clues about sourcing and working materials. Computer simulations test the feasibility of proposed construction methods. This new wave of research continues to shed light on the incredible skills of ancient builders, grounded in evidence rather than speculation.

Conclusion: A Legacy of Human Ingenuity

The ancient engineering wonders that still stand today are more than just impressive ruins; they are profound testaments to the enduring power of human creativity, perseverance, planning, and the ability to collaborate on a massive scale. Even without the technological advantages we possess, these civilizations conceived and executed projects that transformed landscapes and created structures lasting millennia.

Understanding how they achieved these feats, even through theoretical reconstruction, deepens our appreciation for the practical knowledge, organizational skills, and sheer determination of past societies. From the precise alignments of Egyptian pyramids to the earthquake-resistant walls of Machu Picchu and the vast networks of Roman aqueducts, these structures demonstrate that ingenuity is not solely a product of technology, but a fundamental aspect of the human spirit. They stand as a powerful legacy, reminding us of what is possible when vision, skill, and collective effort combine.

FAQ

Q1: How did ancient civilizations move such heavy stones?

A1: Common theories involve using simple machines like levers and rollers, employing sledges pulled over prepared surfaces (like sand wetted with water), and potentially using specific wooden or rope mechanisms. Large numbers of laborers working together were essential.

Q2: Did the Egyptians use slave labor to build the pyramids?

A2: While slavery existed in ancient Egypt, evidence from worker camps and tombs suggests the primary labor force for the great pyramids at Giza consisted of skilled, organized laborers and craftsmen who were housed, fed, and compensated, not primarily slaves.

Q3: How did the Romans build aqueducts with precise slopes?

A3: Roman engineers used surveying tools like the chorobates (a type of level) and dioptra to measure elevations and plan routes that maintained a consistent, slight downward gradient over long distances, often following the natural contours of the land or using arches to cross valleys.

Q4: Why does Inca stonework fit together so tightly without mortar?

A4: The Inca mastered ashlar masonry, precisely cutting and shaping stones to fit together like puzzle pieces. This was likely achieved through repeated hammering with harder stones and abrasion. The tight fit created strong, stable walls that could flex slightly during earthquakes, making them highly resistant to seismic activity.

Q5: Are there still mysteries about how these structures were built?

A5: Yes, absolutely. While plausible theories exist for many aspects, the exact step-by-step processes, specific tools used for intricate cuts, and the precise methods of organizing and motivating vast workforces are still subjects of ongoing research and debate among experts.