The Enduring Mystery of Roman Concrete

Step outside today and look at modern concrete structures. Many built just decades ago are already showing signs of wear, cracks, and decay. Now, consider magnificent Roman buildings like the Pantheon in Rome, which has stood proudly for nearly 2,000 years. Its massive, unreinforced concrete dome remains a marvel of engineering and material science. This striking contrast poses a fundamental question: what made Roman concrete so incredibly durable, especially in harsh environments like corrosive seawater ports, where modern concrete struggles to last even 50-100 years?

For centuries, the exact recipe and techniques behind this ancient supermaterial were lost to time, viewed as an almost mythical secret. However, modern scientific research, leveraging advanced analytical tools, has begun to rediscover the hidden chemistry and innovative methods that gave Roman concrete its unparalleled longevity. This post will explore the limitations of modern concrete, reveal the unique ingredients and mixing techniques of the Romans, delve into the complex chemistry and self-healing properties of their material, showcase iconic examples of its durability, and discuss current efforts to replicate this ancient technology for future sustainable construction.

Why Modern Concrete Crumbles (Comparatively)

The Limitations of Ordinary Portland Cement

Modern concrete primarily relies on Ordinary Portland Cement (OPC) as its binder. This cement is produced by heating limestone and clay at high temperatures, then grinding the resulting clinker. When mixed with water, OPC undergoes hydration, forming Calcium-Silicate-Hydrate (C-S-H) gel, the main binding phase, and calcium hydroxide (Ca(OH)₂). This process binds together aggregates like sand and gravel to create the hard, solid material we know.

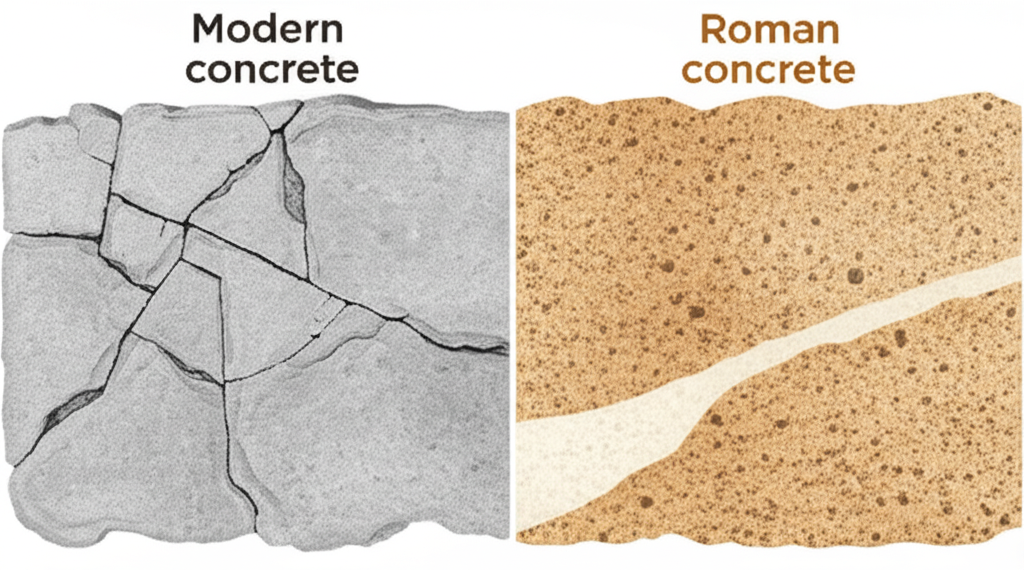

While effective, modern concrete typically has a design lifespan of 50 to 100 years. It is susceptible to various forms of degradation. Common failure mechanisms include freeze-thaw damage, where water expands upon freezing within pores, cracking the material. Sulfate attack and alkali-silica reaction (ASR) involve aggressive chemical reactions with sulfates or certain aggregates, causing expansion and cracking. Chloride ingress, often from seawater or de-icing salts, corrodes the steel reinforcement within the concrete, leading to spalling and structural failure.

The inherent porosity of modern concrete allows water and aggressive substances to penetrate easily, accelerating these damaging processes. Furthermore, the production of Portland cement is highly energy-intensive and is a significant contributor to global CO2 emissions, raising environmental concerns about its widespread use.

Unearthing the Secrets: Ingredients of Roman Concrete

The Volcanic Magic: Pozzolana and Aggregates

A key difference in Roman concrete lies in its binder system. Instead of relying solely on heated clinker like modern cement, the Romans used a mixture of lime and a special volcanic material called pozzolana (known to them as pulvis Puteolanus). Pozzolana, named after the region of Pozzuoli near Naples where it was abundant, is volcanic ash or tuff rich in reactive silica and alumina.

Pozzolana itself isn’t a binder. Its magic happens when it reacts chemically with calcium hydroxide in the presence of water. This “pozzolanic reaction” forms new, stable cementing compounds. The aggregates used by the Romans were also critical. Often sourced locally, they frequently included fragments of volcanic rock like basalt or tuff, which themselves contained reactive silica. In areas without suitable volcanic rock, crushed ceramic materials like brick or pottery shards were used as alternative reactive aggregates.

The Lime and the ‘Hot Mixing’ Technique

The source of calcium hydroxide in Roman concrete came from quicklime (calcium oxide, CaO), produced by heating limestone. While modern concrete production involves slaking the quicklime into a paste before mixing, evidence suggests the Romans used a technique researchers call ‘hot mixing’. This likely involved adding quicklime directly to the mix of pozzolana and aggregates, along with very hot water.

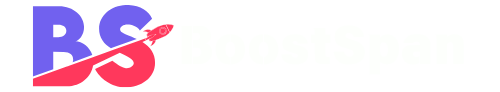

This hot mixing process created extremely high temperatures, potentially up to 200°C (392°F), within localized areas of the concrete during mixing. This heat had crucial effects. It promoted rapid chemical reactions and led to the formation of small, highly reactive inclusions or ‘clasts’ of lime and related compounds scattered throughout the mix. These features, identifiable under microscopy, were previously thought to be evidence of poor mixing but are now understood as intentional, key components contributing to the concrete’s longevity and self-healing capabilities.

The Chemistry of Ancient Strength: Beyond Simple Hydration

The Pozzolanic Reaction and C-A-S-H Gel

The chemical reactions in Roman concrete are more complex and beneficial than the simple hydration of Portland cement. The pozzolanic reaction involves the calcium hydroxide (from the lime and the hot mixing process) reacting with the reactive silica and alumina present in the pozzolana and volcanic aggregates. This reaction occurs slowly over time in the presence of water.

The primary binding product formed is Calcium-Aluminum-Silicate-Hydrate (C-A-S-H) gel. Unlike the C-S-H gel in modern concrete, the Roman version incorporates aluminum into its structure. This inclusion, combined with the specific formation process driven by the pozzolanic reaction and hot mixing, results in a C-A-S-H gel that is often denser, less permeable, and more chemically stable than its modern counterpart, particularly in aggressive environments.

The Role of Stable Crystalline Phases

Beyond the C-A-S-H gel, Roman concrete develops specific, highly stable crystalline minerals within its matrix over long periods. Two key phases researchers have identified are Stratlingite (a calcium-alumina-silicate hydrate) and, significantly, aluminum-substituted Tobermorite. Tobermorite is a form of C-S-H with a layered crystalline structure, and its aluminum-substituted version found in Roman concrete is particularly stable and rare in modern materials.

These crystals grow over decades and centuries. They effectively fill in the microscopic pore spaces and microcracks that naturally form in concrete, a process called crystallization. This continuous growth reduces the material’s permeability, making it increasingly resistant to the penetration of water and harmful chemicals like sulfates and chlorides. Their formation and stability are a major reason for Roman concrete’s resistance to chemical attacks that degrade modern concrete.

The Self-Healing Mechanism Explained

Perhaps the most remarkable discovery about Roman concrete is its inherent ability to self-heal. This property is directly linked to the ‘lime clasts’ and other reactive inclusions created by the hot mixing technique. These inclusions are rich in reactive calcium compounds (calcium oxide/hydroxide) and unreacted pozzolana.

When microcracks form in the concrete—a common occurrence due to drying shrinkage, thermal expansion, or structural stress—they create pathways for water to enter. When water reaches these embedded reactive lime and pozzolana inclusions, it dissolves them. This dissolved material then reacts within the confines of the crack, forming new crystals of C-A-S-H gel and, crucially, calcium carbonate (calcite).

These newly precipitated minerals fill the crack, effectively sealing it and preventing further water ingress or propagation of the crack. Recent research, including detailed analysis of Roman harbor concrete samples submerged for millennia, has provided definitive evidence of this process occurring naturally over vast timescales. This isn’t just a superficial crack-filling; it’s a chemical repair mechanism embedded within the material itself.

Built to Last: Famous Examples of Roman Concrete Durability

Iconic Structures on Land

Roman concrete proved revolutionary for construction on an unprecedented scale and complexity. The Pantheon in Rome stands as a testament to its terrestrial strength. Built around 126 AD, its massive dome, spanning over 43 meters (142 feet) without reinforcement, remains the world’s largest unreinforced concrete dome. The exceptional preservation is due in part to the concrete’s quality, including the use of lightweight volcanic aggregates like pumice in the upper sections to reduce load while maintaining strength with the durable pozzolanic binder.

The grand Baths of Caracalla and Baths of Diocletian are other prime examples. These structures demonstrate concrete’s versatility in creating vast vaulted spaces, massive walls, and complex geometries like domes, semicircles, and arches. Their extensive remains show how Roman engineers leveraged concrete’s ability to be cast into virtually any shape, a key factor in their ambitious architectural designs, alongside its inherent durability.

Enduring Marine and Aquatic Infrastructure

Perhaps the most impressive demonstration of Roman concrete’s superiority over modern counterparts is its performance in marine environments. Roman ports like Portus near Rome and Caesarea Maritima in modern Israel featured jetties, breakwaters, and harbor walls built using concrete, submerged in aggressive saltwater for 2,000 years. Unlike modern concrete, which is highly susceptible to sulfate attack and chloride-induced corrosion in seawater, Roman marine concrete has survived remarkably well.

This resilience is attributed to its specific chemistry. The formation of stable crystalline phases like aluminum-substituted Tobermorite is enhanced by the chemical interactions with seawater. This process, combined with the low permeability achieved through crystalline growth and the active self-healing triggered by the continuous presence of water, allowed the concrete to withstand the constant chemical and physical stress of the marine environment for millennia, a feat largely unmatched by modern materials. Roman aqueducts and reservoirs also utilized concrete, demonstrating its durability against constant freshwater exposure and hydrostatic pressure.

Modern Science Replicates Ancient Wisdom

Analyzing the Past

Understanding the secrets of Roman concrete required peering into its ancient microstructure. Modern materials scientists have employed sophisticated techniques to analyze samples from Roman ruins. These include Scanning Electron Microscopy (SEM) to view the material’s texture and components at high resolution, Energy-dispersive X-ray spectroscopy (EDX) and X-ray Diffraction (XRD) to identify the elemental composition and crystalline phases present, and powerful tools like Synchrotron radiation for detailed chemical mapping.

These analyses were pivotal. They confirmed the presence of the reactive ‘lime clasts’ resulting from hot mixing and definitively identified the specific stable minerals like Stratlingite and aluminum-substituted Tobermorite as crucial binding phases responsible for long-term strength and durability. This research highlights the value of interdisciplinary collaboration, bringing together archaeologists, historians, geologists, and engineers to unlock historical technological achievements.

Replicating Roman Concrete Today

Armed with this knowledge, modern researchers are actively working to replicate the properties of Roman concrete. Efforts focus on substituting or supplementing Portland cement with natural pozzolana from volcanic sources, or using industrial byproducts like fly ash (from coal combustion) or slag (from metal smelting) which possess similar reactive properties.

However, replicating the exact Roman performance presents challenges. Sourcing consistent, high-quality natural pozzolana in large quantities can be difficult. Achieving the precise microstructure, distribution of reactive components (like the lime clasts), and control over the hot mixing effects that the Romans intuitively managed is complex on an industrial scale. Despite these hurdles, successful replication attempts have been made in laboratory settings, demonstrating similar resistance to cracking, reduced permeability, and enhanced durability compared to standard modern mixes when tested under harsh conditions.

Implications for the Future of Construction

Towards More Sustainable and Resilient Structures

Rediscovering the secrets of Roman concrete offers profound implications for the future of construction. Environmentally, incorporating reactive supplementary cementitious materials like pozzolana or industrial byproducts can significantly reduce the amount of energy-intensive Portland cement needed, thereby lowering the CO2 footprint of concrete production. Utilizing industrial byproducts also promotes a more circular economy.

Economically and societally, building structures with significantly longer lifespans—potentially hundreds or even thousands of years—would dramatically reduce long-term costs associated with maintenance, repair, and replacement of infrastructure. Imagine bridges, tunnels, or coastal defenses that require minimal upkeep for centuries. This resilience is particularly valuable in challenging environments where modern materials currently degrade prematurely, such as:

- Coastal defenses and marine structures constantly exposed to saltwater.

- Infrastructure in regions with harsh freeze-thaw cycles.

- Specialized applications like geothermal wells or long-term nuclear waste storage, where extreme conditions demand ultimate durability.

Conclusion

The extraordinary longevity of Roman concrete, especially its remarkable performance in aggressive environments like seawater, is no longer a complete mystery. Modern scientific analysis has revealed that its strength lies in a combination of specific, reactive ingredients—primarily lime and volcanic pozzolana—and an innovative ‘hot mixing’ technique. These elements work together to create a unique chemistry that forms stable crystalline phases like Stratlingite and aluminum-substituted Tobermorite and, crucially, bestows the material with an intrinsic self-healing capability triggered by water.

This sophisticated understanding demonstrates that Roman engineers possessed an intuitive mastery of materials science that, in certain contexts, produced concrete superior in durability to many modern mixes. By studying and replicating this ancient wisdom, we gain valuable insights into developing the next generation of building materials—materials that are not only incredibly strong and durable but also potentially more sustainable, offering hope for constructing a future where infrastructure lasts for millennia, not just decades.

FAQ

Q: Is Roman concrete stronger than modern concrete in every way?

A: Not necessarily in terms of initial compressive strength, which modern concrete can achieve very high levels of quickly. However, Roman concrete excels in long-term durability and resistance to chemical degradation and cracking, particularly in harsh environments like saltwater, where it often outperforms modern mixes over centuries.

Q: What were the key ingredients that made Roman concrete different?

A: The most crucial differences were the use of lime and pozzolana (volcanic ash/tuff) as binders, rather than relying solely on the heated clinker of Portland cement. Additionally, the type of aggregates, often volcanic rocks, played a reactive role, and the ‘hot mixing’ technique was vital.

Q: How does Roman concrete “self-heal”?

A: The ‘hot mixing’ process created reactive inclusions (like lime clasts) within the concrete. When microcracks form and water enters, it dissolves these inclusions, which then react to form new crystals (like C-A-S-H and calcite) within the crack, sealing it and preventing further damage.

Q: Can we make buildings like the Pantheon today using the Roman method?

A: While modern researchers have successfully replicated small batches with similar properties in the lab, scaling up the production economically and consistently using the exact Roman methods and materials presents significant challenges. However, the principles discovered are informing the development of new, more durable and sustainable modern concrete mixes.

Q: Why did the Romans stop using this superior concrete?

A: The knowledge and techniques likely became less widespread and eventually lost with the decline of the Roman Empire, the disruption of trade routes (making specific pozzolana sources harder to access), and changes in construction practices and societal priorities over the subsequent centuries.